3D Scanning in Concrete Construction: Workflow Guide

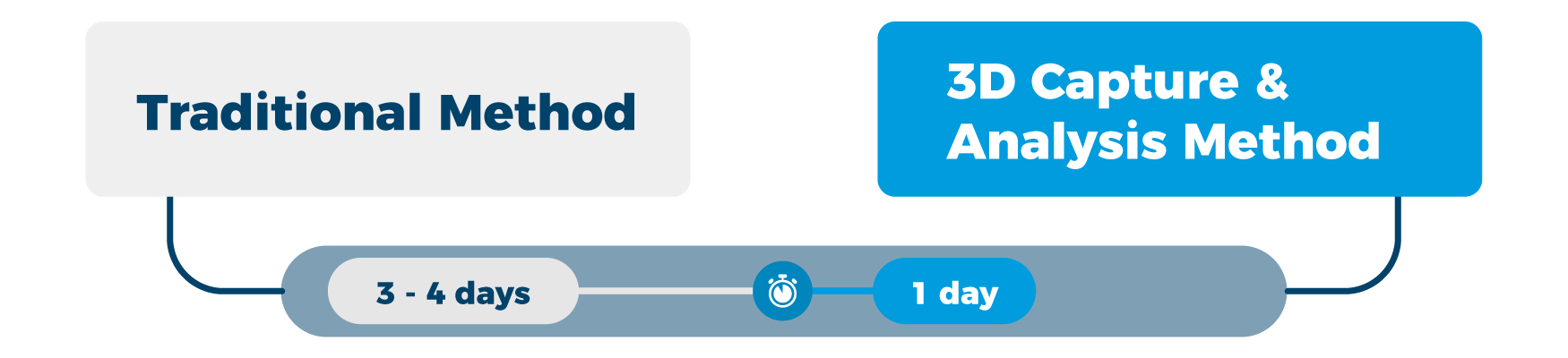

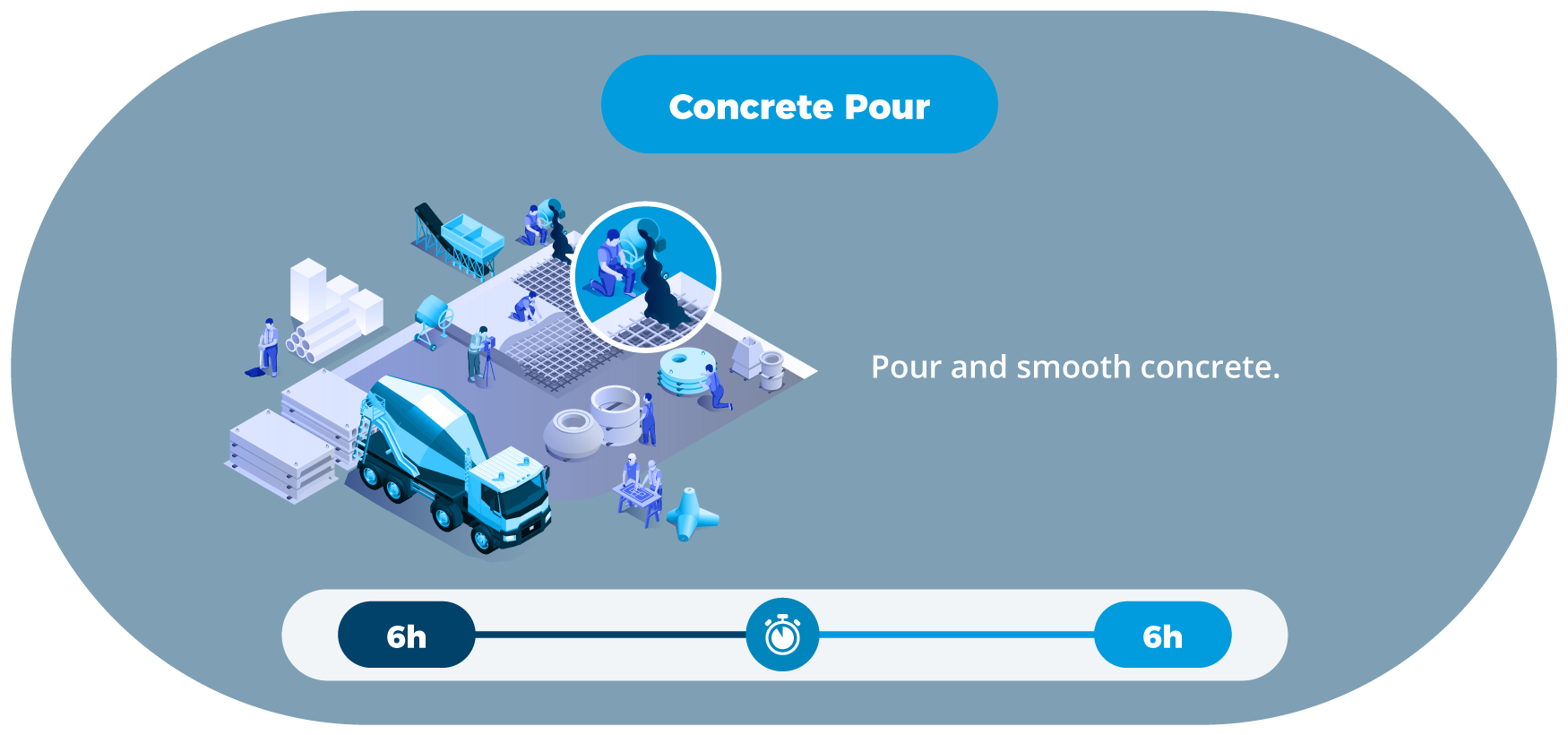

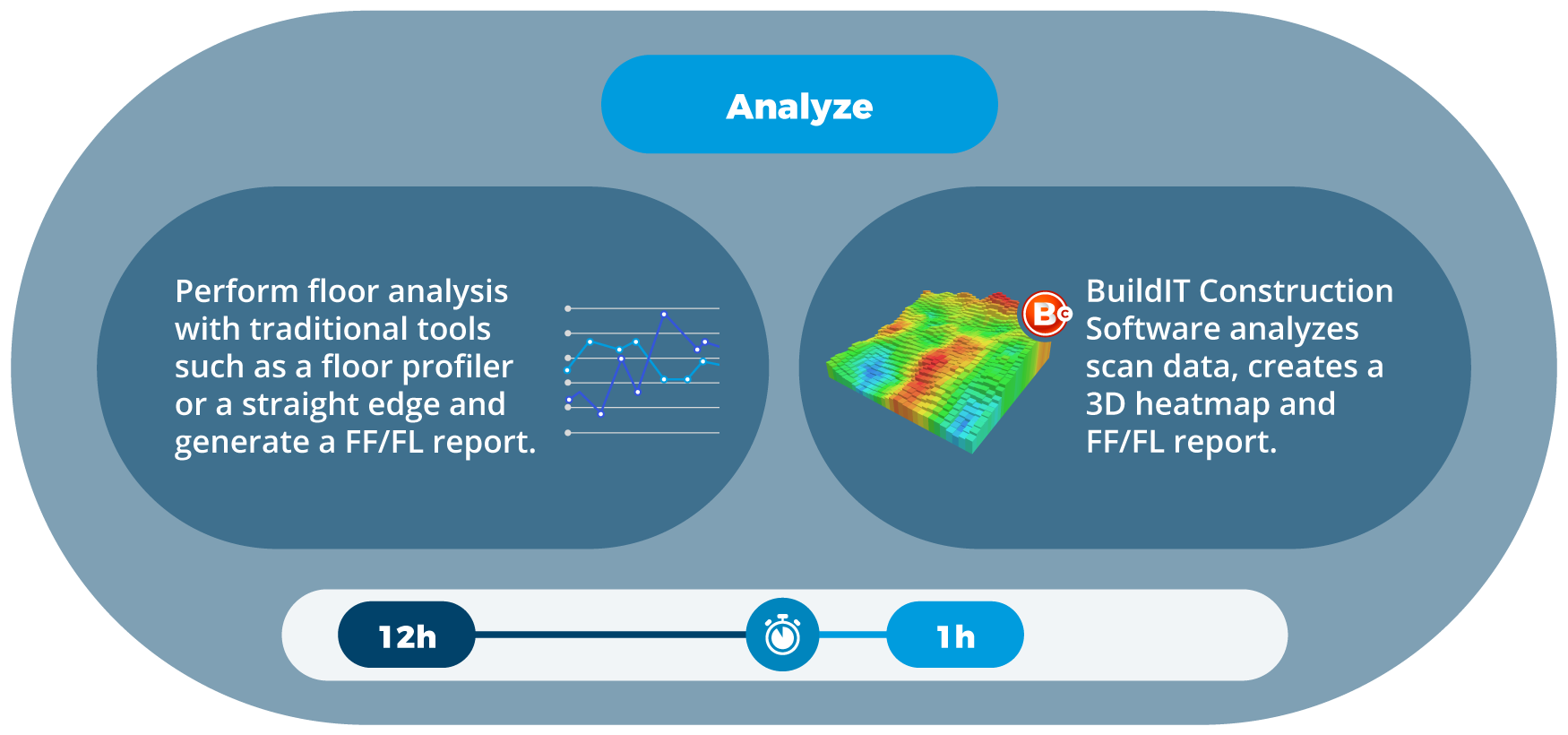

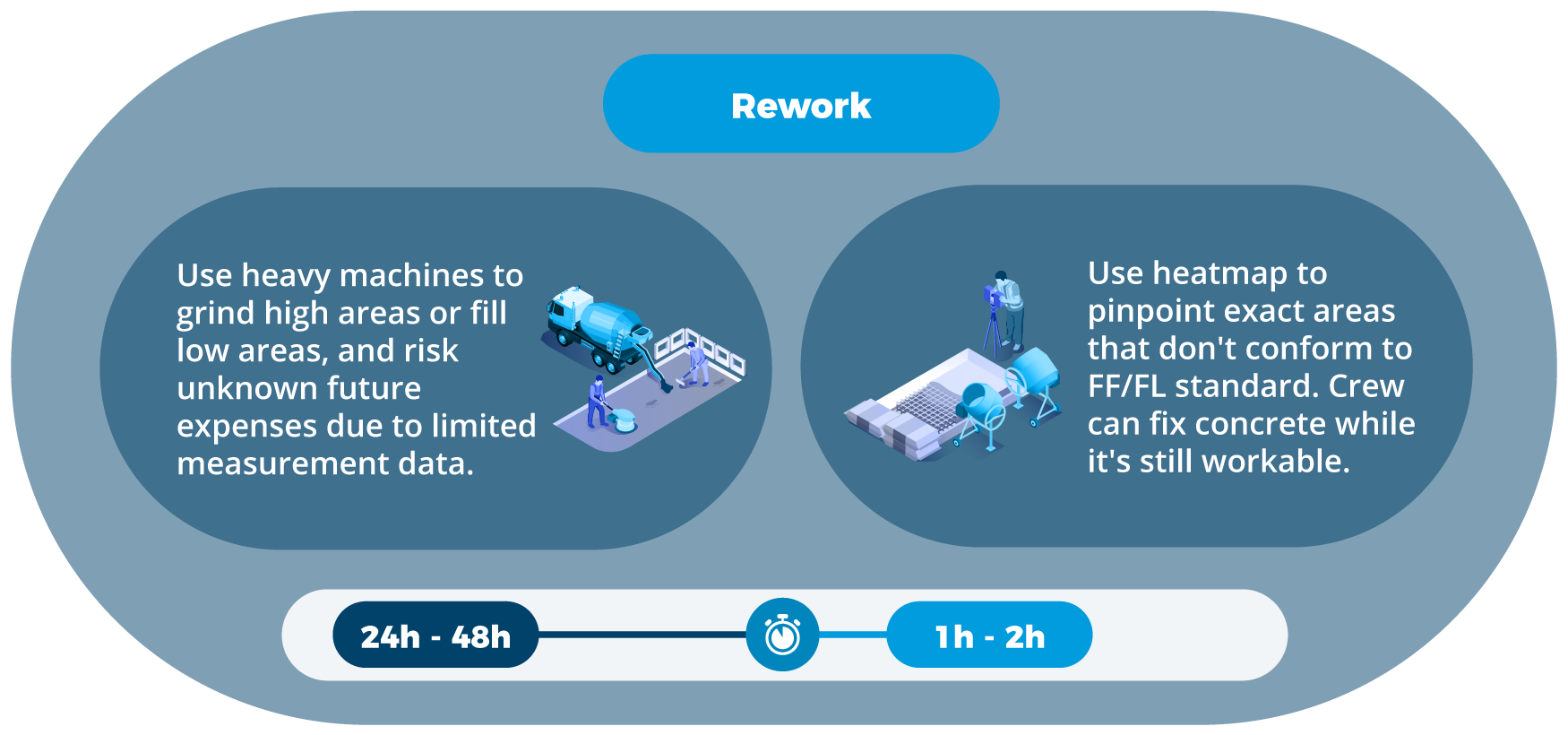

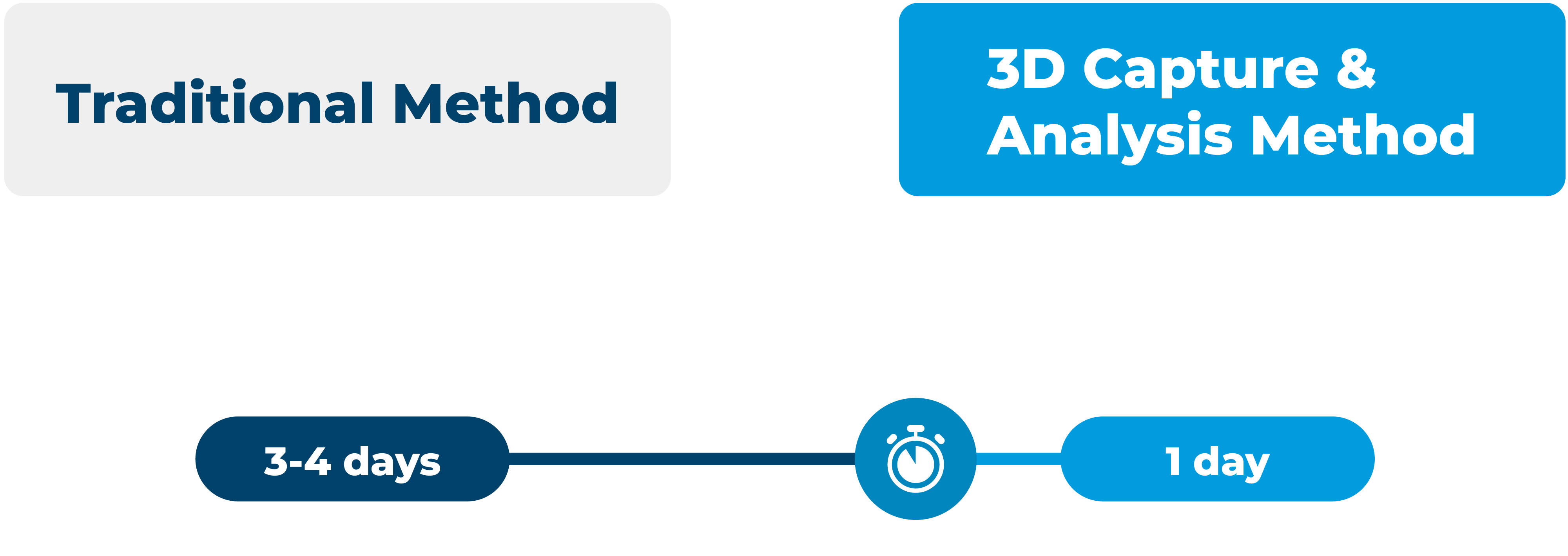

This guide compares the 3D reality capture process with more conventional methods of measuring concrete slabs to assess FF/FL specifications.

Download to learn:

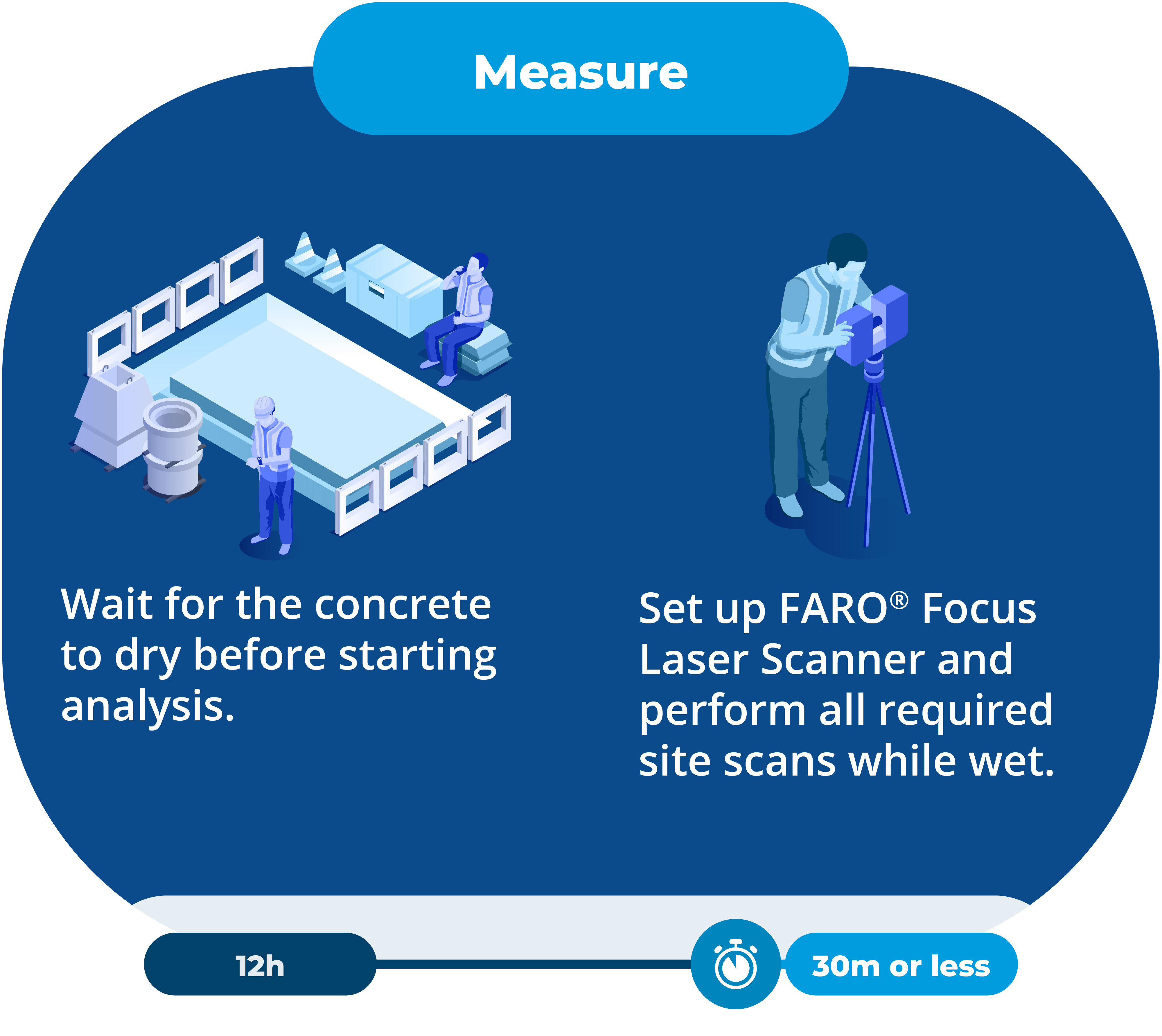

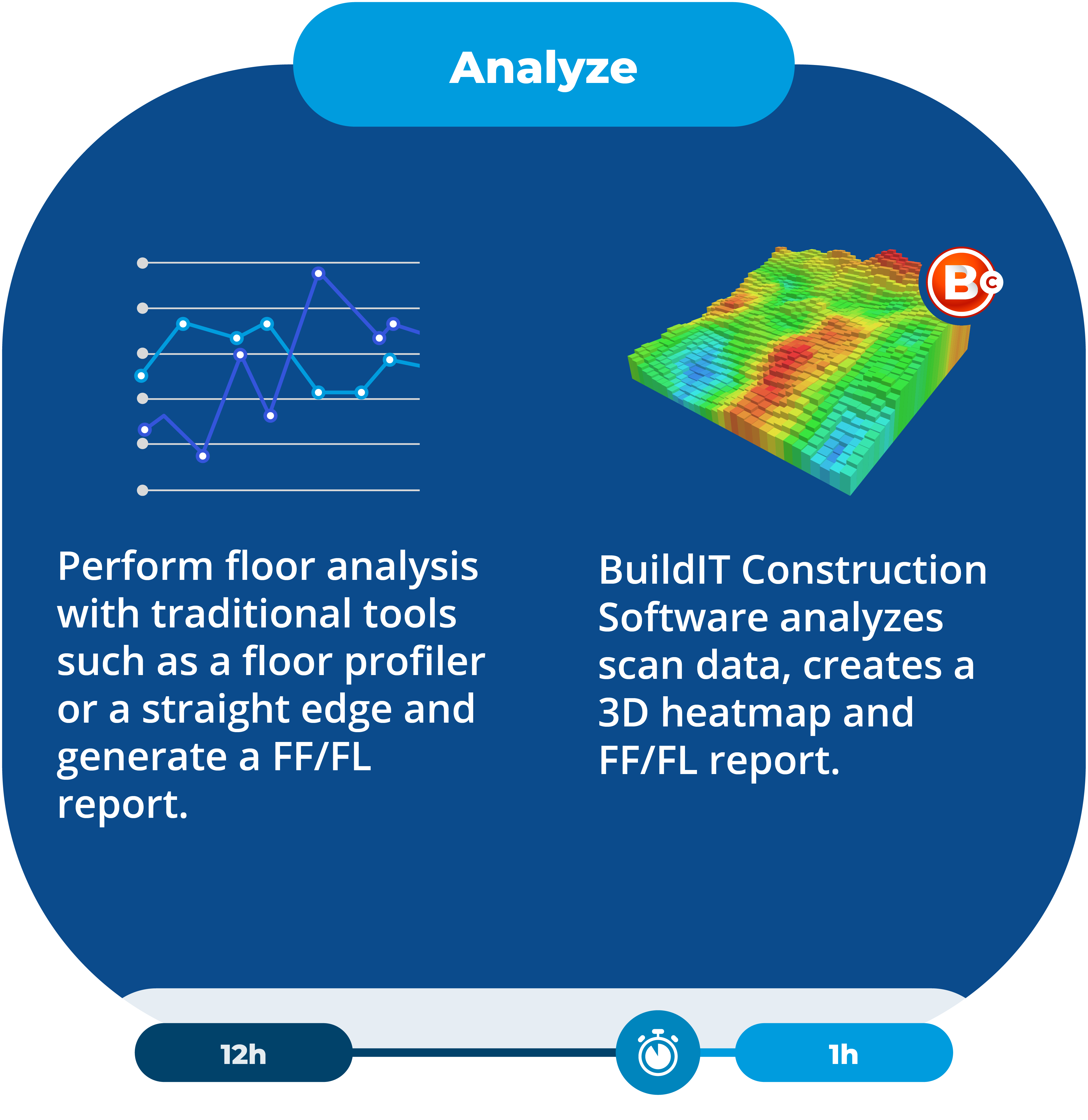

- Why concrete construction verification using the FARO® Focus Laser Scanner and BuildIT Construction Software is superior to traditional methods.

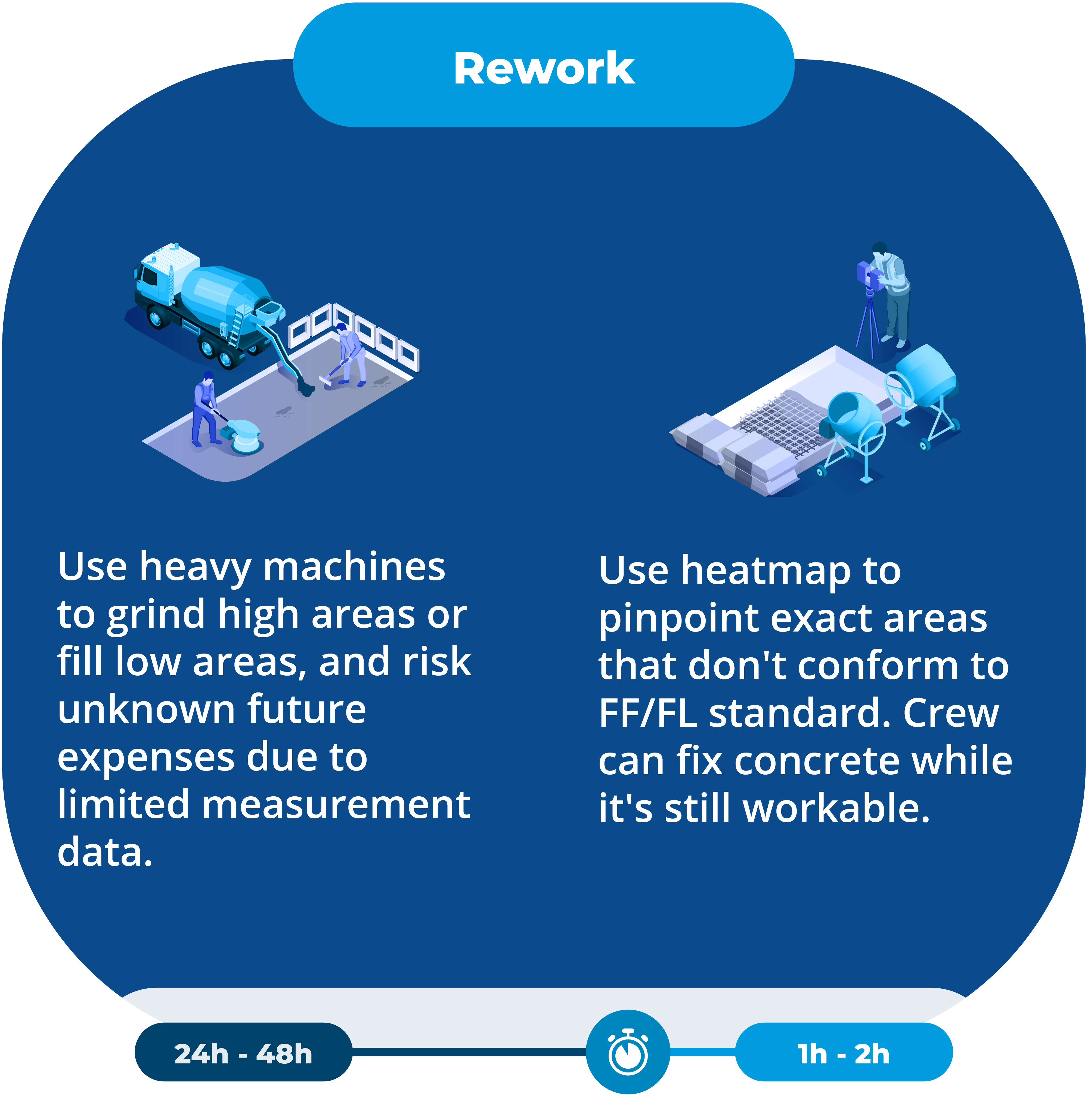

- How using a 3D data capture solution allows work crews to patch up any identified dips and swells while the concrete is still workable — saving you time and money.

- An illustrated side-by-side comparison of the 3D Data Capture workflow vs. traditional methods.

Watch how DPR addressed concrete pour challenges in real time with laser scanning, to meet the strict FF/FL standards required by their client.

See how Baker implemented a FARO 3D Laser Scanner into their project workflow to manage site logistics, concrete prefabrication, and steel embed measurements.

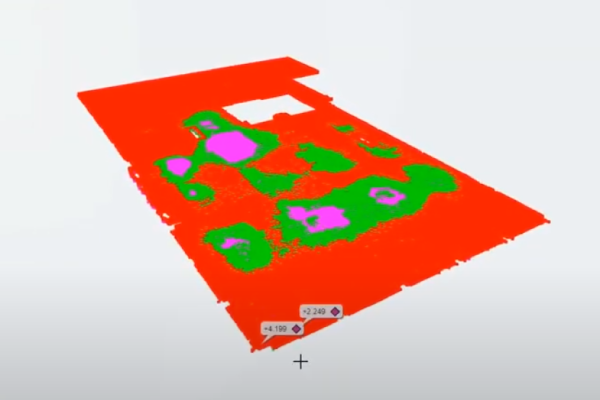

The construction firm deploys a 3D Laser Scanner to evaluate FF/FL of concrete slabs, automate verification processes, and improved deliverability to clients.

A step-by-step tutorial of how to use the BuildIT software to generate a 3D model of a concrete slab, gauge FF/FL, and identify any out-of-tolerance areas.

Ready to talk about improving quality and efficiency in your next concrete project?

“Concrete is probably the best application of the scanner. I can see the appeal for GCs wanting to document their work, it carries over from what we want to do. We’re using it on the front-end side of the job to control or inform our logistics, so that we don’t get in a bad situation.”

Senior BIM/VDC Designer,

Baker Concrete Construction