The Complete Guide to 3D Technology for Sheet Metal Stamping

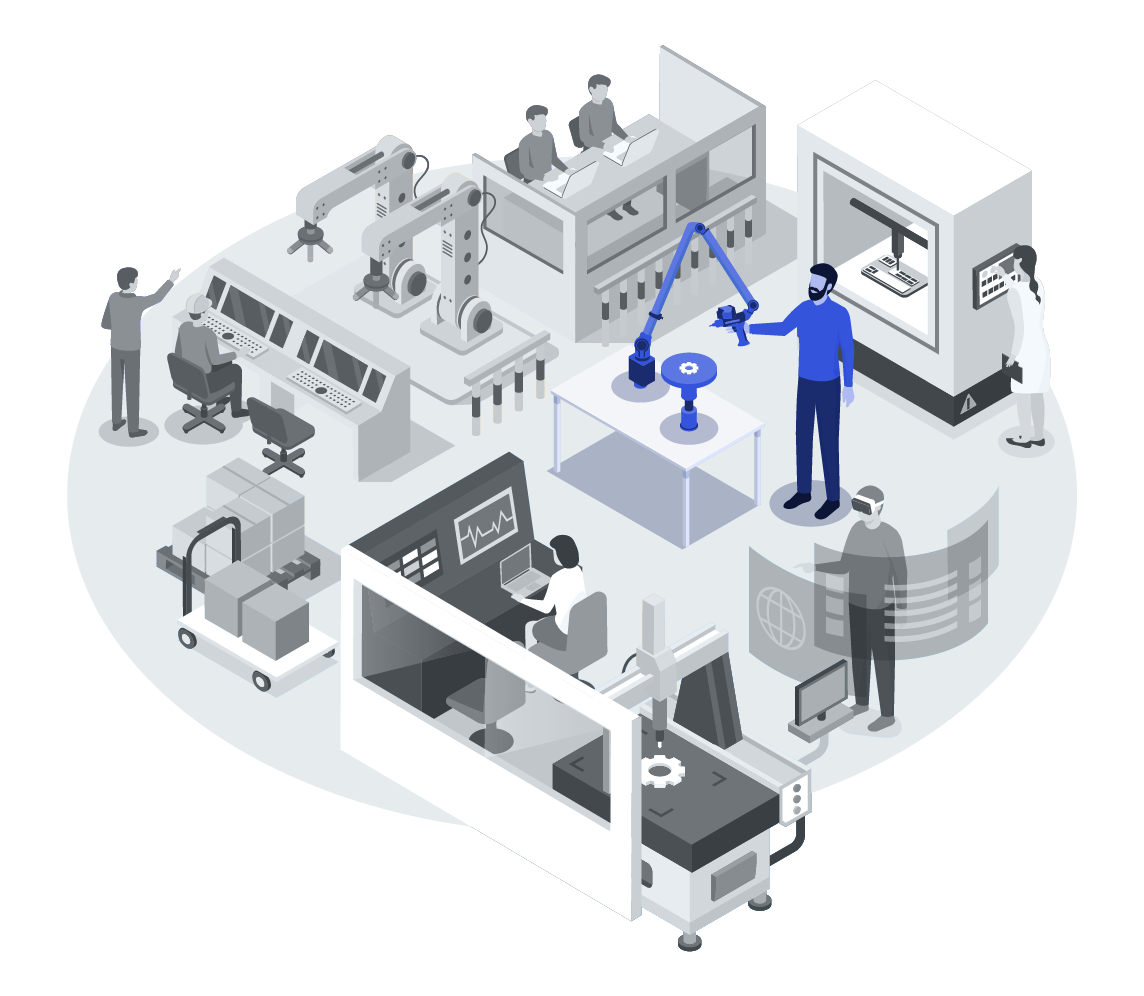

Sheet metal stamping has many applications that demand extreme precision, and the tiniest error can set off a chain reaction of costly delays or even safety issues. 3D scanning technology offers greater precision, speed, and ease of use than traditional fixed CMM systems, enhancing yield, increasing customer loyalty and generating more revenue.

Download this guide to learn:

- How 3D portable measurement solutions simplify the entire metal stamping workflow to accelerate production, inspection and quality control while achieving greater precision and accuracy.

- The various ways the Quantum Max FaroArm and ScanArm can benefit your business and simplify your workflow.

- How the Quantum Max increases both efficiency and precision across every step of QA and inspection processes.

From start to finish, 3D laser scanning vastly enhances the speed and quality of measurements taken in metal stamping for all industries.

Taylor Metal Products keeps the automotive supply chain flowing, saving time and money, with the help of the FARO ScanArm.

UK company uses blue laser technology to achieve precision results on complex, dark, and reflective materials common in automotive applications.

Ready to talk about improving quality and efficiency in your next metal stamping project?

“Using the FARO ScanArm has gotten us out of million-dollar recall by enabling us to prove to the customer that a manufacturing issue started with their engineering print. In addition, FARO solutions make it easier to communicate with our customers — especially overseas customers, like the Japanese automotive manufacturers.”

Quality Engineer, Taylor Metal Products